INTRO

About Dazhan

Dazhan Automation is located in Tainan, Taiwan. From custom equipment manufacturing, production line planning, and video visualization, we serve customers from traditional industries to technology industries.

From machine design, machine assembly, electric control and power distribution, software programming, equipment calibration, testing machines, delivery to after-sales service, all are done by the elite of all departments of Dazhan Automation.

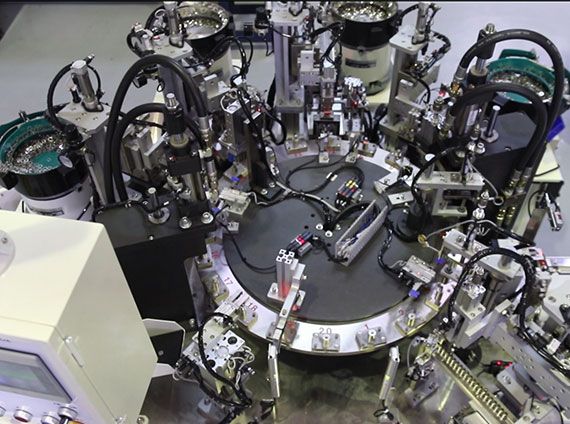

Reflector automatic machine

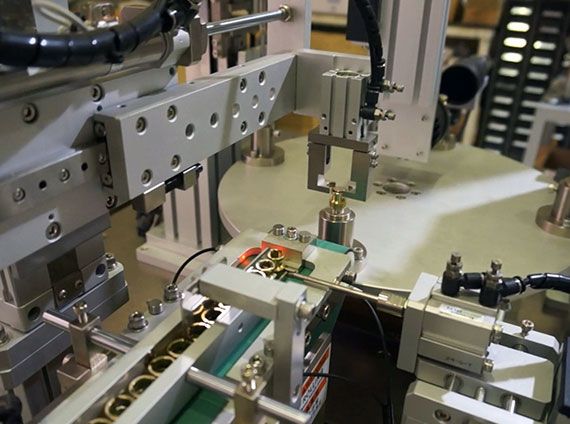

BNC connector automatic machine.

Hardware Component

Automatic Machine.

Our Vision

We specialize in automated custom equipment, thinking about each link and handling each detail, keeping the mindset of solving problems for enterprises to face, all just to complete a dedicated to your equipment.

Not to be bound by the conservative concept of the process, technology continues to improve, facilitate, experience as the basis, innovative technology as a supplement, to build a device. The integration of technology and resources will open the vision of our professionals, technology from all directions, resources from various manufacturers around the world, a stable interconnection network will develop our technology to infinite possibilities.

Quality

Dazhan Automation's quality policy is "continuous improvement to provide customer satisfaction in quality and service". Through various production process improvement, personnel education and training, and product quality control measures, as well as the participation and efforts of all factory personnel, the quality policy can be implemented in the smallest detail.

Service

The SOP standard process is established to make the use of equipment simple and easy for customers, and the maintenance department will handle the SOP process at the first time according to the valuable information from customers to shorten the maintenance time.

Research&Development

We are actively engaged in research and development of innovative special mechanisms and systems, constantly growing, falling down, testing and failing in order to provide a set of systems and mechanisms to our customers. What we do is not only the equipment, but the attitude of giving with heart and soul. Only by keeping this attitude can we finish a satisfactory automatic equipment.

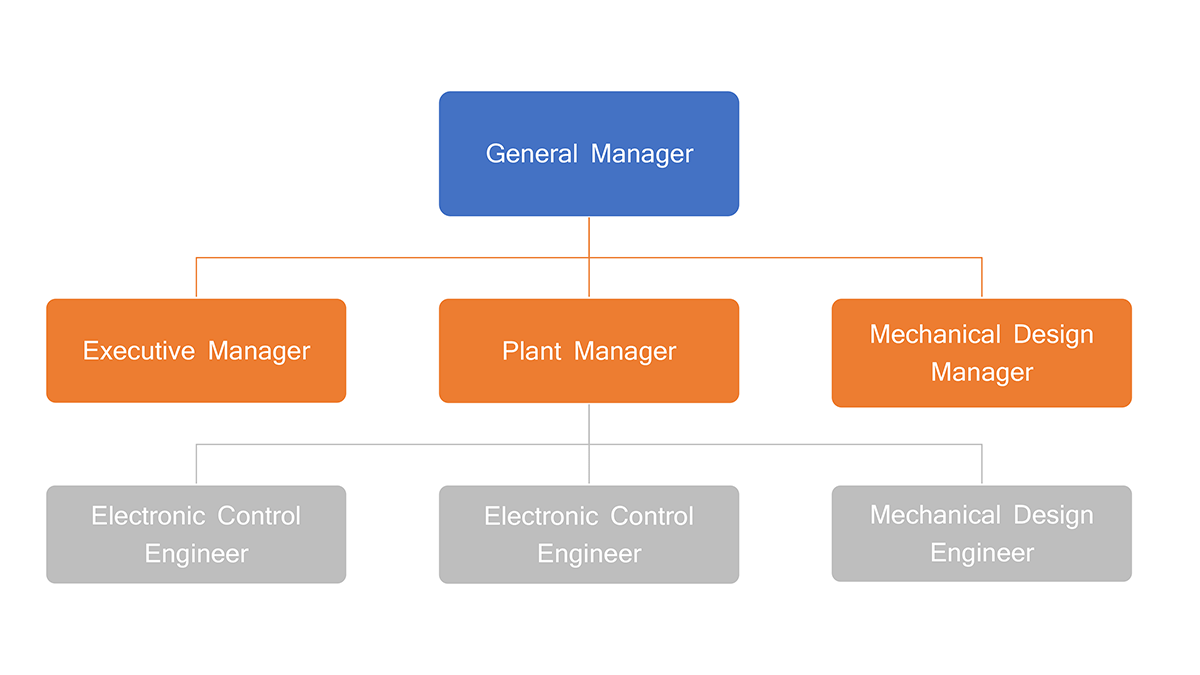

Our Organization

Industry

Automated assembly machine

Example: screws, fasteners, hardware, door locks, electronic connectors, reflectors, home appliances

ROBOT application

Example: Moving, disassembly and transportation, parts disassembly and assembly

AOI machine、Sorting Machine

Example: Screws, fasteners, hardware, finished products, batteries (poles), electronic parts

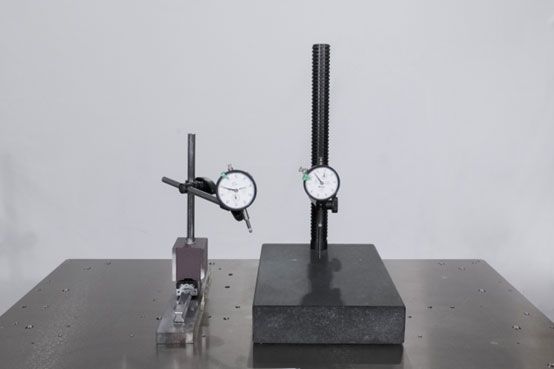

Inspection Equipment

Vernier calipersz

Japan Mitutoyo standard vernier calipers, accuracy 0.01mm.

Height Gauge(Right)

Use Japanese Mitutoyo gauges to measure height, bore depth, and parallelism.

Mobile Percentage Watch(left))

Use Japanese Mitutoyo scale to measure the angle, parallelism, height difference and mechanical calibration.